Zertifikate & Bestandslisten

Sustainable supply chain excellence - delivered!

We supply and move steel - globally - in numerous specifications - and with typical "made in Switzerland" reliability.

AFV Beltrame Gruppe

Documents & downloads

AFV Beltrame is a strong, competitive and leading steel group. Synergistic technologies, state-of-the-art know-how and first-class management consolidate the market position of this group of companies as Europe’s leading supplier of bulk steels and confirm its unwavering success in the steel industry.

AFV Beltrame Group - AFV: San Didero, Italy

Certificates | Stock lists |

| ISO 9001:2015 (PDF) | AFV Stock lists Standard (PDF) |

| ISO 14001:2015 (PDF) | AFV Stock lists noStandard (PDF) |

| ISO 45001:2018 (PDF) | |

| AFV Declaration of Performance (PDF) | |

| AFV EU Directive (PDF) |

AFV Beltrame Group - AFV: San Giovanni Valdarno, Italy

Certificates | Stock lists |

| ISO 9001:2015 (PDF) | AFV Stock lists Standard (PDF) |

| ISO 14001:2015 (PDF) | AFV Stock lists noStandard (PDF) |

| ISO 45001:2018 (PDF) | |

| AFV Declaration of Performance (PDF) | |

| AFV EU Directive (PDF) |

AFV Beltrame Group - AFV: Vicenza, Italy

Certificates | Stock lists |

| ISO 9001:2015 (PDF) | AFV Stock lists Standard (PDF) |

| ISO 14001:2015 (PDF) | AFV Stock lists noStandard (PDF) |

| ISO 45001:2018 (PDF) | |

| AFV Declaration of Performance (PDF) | |

| AFV EU Directive (PDF) |

AFV Beltrame Group - Donalam: Calarasi, Romania

Certificates | Downloads |

| ISO 9001:2015 (PDF) | AD 2000-Fact sheet W 0 (PDF) 338 KB |

| ISO 14001:2015 (PDF) | Lloyds Register (PDF) 504 KB |

| ISO 45001:2018 (PDF) | Approval of Manufacturer Certificate DNV (PDF) 504 KB |

| EOHS 2020 (PDF) | |

| Certificate of conformity of factory production control for hot rolled products of structural steels (PDF) |

AFV Beltrame Group - LME: Trith-Saint-Léger, France

Certificates | Stock lists |

| ISO 9001:2015 (PDF) | AFV Stock list Standard (PDF) |

| ISO 14001:2015 (PDF) | AFV Stock list noStandard (PDF) |

| ISO 50001:2011 (PDF) | |

| OHSAS 18001:2007 (PDF) | |

| Declaration of Performance (PDF) |

AFV Beltrame Group - Stahl Gerlafingen, Switzerland

Certificates | Stock lists |

| ISO 9001, ISO 14001, OHSAS 18001 (PDF) | Stock list (PDF) |

Feralpi Holding S.p.A.

Documents & downloads

Feralpi is one of the most important steel producers for Italy’s construction industry. Its four subsidiaries Feralpi Siderurgica S.p.A., Acciaierie di Calvisano, Dieffe and Nuova DE.FI.M have several steel mills throughout Italy. In the 1990s, new opportunities and chances opened up. Major investments in existing and new steel mills were particularly promising. During the same time, the two production sites in Riesa – Elbe-Stahlwerke and Elbe-Drahtwerke – were established in Germany.

Feralpi Group

Certificates Lonato, Italien | Calvisano, Italien |

| ISO 9001:2015 (PDF) | TÜV SÜD - Pressure Equipment Directive 2014/68/EU - 2000 Fact sheet W 0 (PDF) |

| ISO 14001:2015 IQNET (PDF) | |

| ISO 14001:2015 IGQ (PDF) | |

| ICMQ 17024EPD (PDF) | |

| ICMQ 17026EPD (PDF) |

Pittini Group

Documents & downloads

The Pittini Group, with its corporate headquarters in Osoppo (IT), is a leading manufacturer of long steel for the construction and engineering industries, with 19 production sites in Italy and abroad and a production capacity of over 3 million tons per year.

Pittini’s strengths are:

- full control of the entire production process, based on the principles of the circular economy and on the recycling of waste products, which are a consequence of the Zero Waste project

- more than 60 years of experience in the steel industry with continuous innovation; constant research to develop products and processes and invest in the best technologies to produce the most advanced steel

- the ongoing training of all employees with the establishment of a Corporate School in 2003, one of the first in Italy

PITTINI® Siderprodukte AG distributes to the following countries: Wire rod – Belgium, Germany, Luxembourg, Netherlands. The reinforcing steel continues to be distributed to Switzerland by SIPRO® Siderprodukte AG.

Acciaierie Venete Group

Documents & downloads

Acciaierie Venete S.p.A. has been producing commodity steel products since 1957: ingots, billets and reinforcing steel. At the beginning of the 1980s, the company began to specialize in quality steel products and, as a result of this evolutionary step, is today one of the most renowned producers in Europe in the engineering steel sector.

This progress of growth took place both internally (through investments in human resources, technology, processes and products) and externally, through the acquisition of production facilities in Sarezzo, Mura, Dolcè in 2003, as well as the steel mill in Borgo Valsugana (formerly BVS) and the rolling mill in Odolo (formerly Leali Steel) in 2018.

VENETE Siderprodukte AG distributes to the following countries:

Trade steel – Poland, Switzerland, Czech Republic, Slovakia, Hungary

Mechanical processing / solid forming – Austria, Belgium, Bulgaria, Croatia, Czech Republic, France, Hungary, Luxembourg, Germany, Netherlands, Poland, Romania, Slovenia, Slovakia, Spain, Switzerland, Turkey

Acciaierie Venete: Buja (Italy)

Certificates | Stock lists |

| ISO 9001:2015 (PDF) | Stock list (PDF) |

| ISO 14001:2015 Buja (PDF) | |

| ISO 50001:2018 Acciaierie Venete Stab Buja (PDF) | |

| Certificate of conformity of factory production control for hot rolled products of structural steels (PDF) | |

| Performance declaration Buja (PDF) | |

| EMAS Buja (PDF) | |

| Performance declaration Buja (ENG/PL) (PDF) |

Acciaierie Venete: Camin (Italy)

Acciaierie Venete: Dolcè (Italy)

Certificates | Certificates |

| ISO 9001:2015 (PDF) | TÜV Nord - AD 2000 Fact sheet W 0 (PDF) |

| ISO 14001:2015 Dolcè (PDF) | TÜV Nord - PED (PDF) |

| ISO 50001:2018 Dolcè (PDF) | Certificate of conformity of factory production control for hot rolled products of structural steels (PDF) |

| Performance declaration Dolcè (PDF) |

Acciaierie Venete: Mura (Italy)

Certificates | Stock lists |

| ISO 9001:2015 (PDF) | Stock list (PDF) |

| ISO 14001:2015 Mura (PDF) | |

ISO 50001:2011 MURA (PDF) | |

| TÜV Nord - AD 2000 Fact sheet W 0 (PDF) | |

| TÜV Nord - PED (PDF) | |

| Leistungserklaerung Mura (PDF) | |

| Certificate of conformity of factory production control for hot rolled products of structural Steels (PDF) |

Acciaierie Venete: Sarezzo (Italy)

Certificates | Certificates |

| ISO 9001:2015 (PDF) | Performance declaration Sarezzo (PDF) |

| ISO 14001:2015 Sarezzo (PDF) | IATF 16949:2016 Acciaierie Venete Sarezzo (PDF) |

| ISO 50001:2011 Sarezzo (PDF) | |

| TÜV Nord - AD 2000 Fact sheet W 0 (PDF) | |

| TÜV Nord - PED (PDF) | |

| Certificate of conformity of factory production control for hot rolled products of structural steels (PDF) |

Acciaierie Venete: Borgo Valsugana (Italy)

Certificates | Certificates |

| ISO 9001:2015 (PDF) | Performance declaration Borgo (PDF) |

| ISO 14001:2015 Borgo (PDF) | TÜV Nord - AD 2000 Fact sheet W 0 (PDF) |

| ISO 14064-1:2018 – Year 2022 (PDF) | TÜV Nord - PED (PDF) |

| KPI ISO 14064-1:2023 (PDF) | |

| ISO 50001:2018 Borgo (PDF) |

Acciaierie Venete: Odolo (Italy)

Certificates | Certificates |

| ISO 9001:2015 (PDF) | Certificate of conformity of factory production control for hot rolled products of structural steels (PDF) |

| ISO 14001:2015 Odolo (PDF) | |

| ISO 50001:2018 Odolo (PDF) | |

| TÜV Nord - AD 2000 Fact sheet W 0 (PDF) | |

| TÜV Nord - PED (PDF) |

Reinosa Forgings & Castings S.L.

Documents & downloads

Reinosa Forgings & Castings is one of the world’s leading manufacturers of large forgings and castings. Our more than one hundred years of experience and growth have allowed us to accumulate knowledge inherited generation after generation through tradition, developing a high know-how and technological level. We provide the best solutions by providing an integral service, from scrap to the final machined product, and our high standards of quality and service.

Certificates | Certificates |

| BV ISO 3834-2 (PDF) | DNV GL Castings AMMM000011H (PDF) |

| BV Steel Forgings (PDF) | DNV GL Forgings AMMM0000103 (PDF) |

| BV Forgings and castings (PDF) | DNV GL Forgings for chain AMMM000012W (PDF) |

| Lloyd's Register - Fittings For Chain Cable (PDF) | ABS approval (PDF) |

| Lloyd's Register - Steel castings (PDF) | ABS certificate (PDF) |

| Lloyd's Register - Steel making and semi finished products (PDF) | ABS certificate offshore mooring (PDF) |

| Lloyd's Register - Steel forgings (PDF) | |

| TüV Annex to Certificate No 01 202 EQ-18 1982 (PDF) | |

| TüV No 01 202 EQ-18 1982 (PDF) |

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Karriere

Together we make the difference

SIPRO® STEEL SOLUTIONS has been operating on the market as a family-run company for more than 50 years. We offer our employees challenging tasks and room for development. Entrepreneurial thinking and acting is a crucial factor in everything we do. We strive to create an environment of responsible cooperation that promotes short decision-making processes.

Focus on people & personal development

We foster our employees through internal and external professional trainings, both with regard to the acquisition of specialist knowledge and also to the development of social skills. As a provider of apprenticeships, we make a valuable contribution to the Group’s future.

Long

company affiliation

Our staff stay with us for an average of 12 years. This shows that our employees feel comfortable with us.

Mobile working & ergonomic workstations

Modern infrastructure allows us to easily meet the requirements of mobile working and home office. In our office, most workstations are ergonomically optimized.

Responsibility

We are always there for each other, even in challenging times: We support young parents during parental leave and ensure a mutually agreed reintegration phase after a longer period of absence due to illness.

Company culture

We are multicultural, speak many different languages and live Mediterranean ease with the reliability of a Swiss timepiece. We achieve our goals together and celebrate good times with a profit-sharing bonus.

We are looking forward to your application!

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Historie

SIPRO® STEEL SOLUTIONS

Wir liefern Stahl

Firmengeschichte

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Environmental, Social and Governance

ESG

Environmental Social Governance

Today, we need to take a closer look not only at what is happening within the company, but also at our external setting: Like any other organization, we are all embedded in an environment for which we, as acting individuals, aim to share responsibility. Anyone who trades on the international stage, as SIPRO does, should also have an overview of the impact of their activities at this level. In this respect, we are guided by three core factors in accordance with the ESG benchmarks:

Environment

The sustainability agenda is on everyone’s lips and no industry that supplies or transports energy-intensive products can be excluded from it. We should and must all ask ourselves how we can contribute to the active fostering of sustainability in the context of our businesses.

The SIPRO Group is part of a network in which production sites, transport companies, customer organizations and other partner entities work together to master the demanding task of steel production and supply. In this respect, everyone is also called jointly to work on improving the environmental situation. Steel production in particular, as well as global transportation, generates considerable CO2 emissions which we aim to reduce in all our joint efforts.

In agreement with all parties involved, we have surveyed our partner companies and suppliers on this topic. It is clear from this that all of them consider the issue of sustainability to be of great importance. The result is now reflected in various initiatives that we will implement in the near future.

As a first step, we intend to achieve full transparency, particularly with regard to the CO2 emissions currently generated, as this is the only way we can identify the key spots we need to address. This project extends from the steel mills where our steel is produced to the transport activities to get the steel to its destination. Thus, in this context, the whole supply chain has to be taken into account.

In the next step we will work specifically on the individual stages to efficiently reduce CO2 emissions “per ton of steel delivered to the customer”. We intend to use “green sourcing” to offer our customers the option of using more climate-friendly sources of supply and transport. By creating transparency across the entire value chain, we are taking the first big approach!

Social

Focusing on social responsibility, we strive to sensitively perceive social interdependencies, dependencies and interrelationships and to ensure that decisions are made with social justice and an ethical perspective in mind.

For us, this means on the one hand guaranteeing fair wages, equal pay and the payment of all social security contributions for the 1st and 2nd pension pillars – as standard from the age of 20. In addition, we emphasize healthy working conditions at ergonomic workplaces. We also bear our responsibility for reintegration after a longer period of illness. In addition, we enable a work-life balance with flexible working hours and home office for all.

We foster fair and cooperative teamwork on a regular basis, both internally and externally, in our dealings with customers and partners. With our training programs in the commercial and IT sectors, we contribute to the professional advancement of the younger generation.

Governance

The third aspect in the ESG context is the implementation of responsible corporate governance. By that we mean targeted initiatives to ensure that our business partners can rely on trustworthy and reputable business practices.

One of the key drivers of our efforts is an always up-to-date risk assessment that extends to all levels of our business. This includes the evaluation and management of our digital processes, which are exposed to particular risks in times of ubiquitous networking and multiple interfaces. Responsible management of our liquid assets contributes to the stability and reliability of our company.

The past few years have shown how fragile supply chains can be in the global market. As logistics processes are the focus of our service, we also continuously assess our logistics planning as well as our service providers and all interfaces to identify weaknesses and develop alternatives.

We also consider the well-timed planning of the generational handover in management to be a further central aspect. To this end, far-reaching preparations are already being made today and resources are being built up to ensure a smooth transition that will result in reliable and stable processes for all stakeholders.

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Digitalisierung

Digitization

Full tracking of orders

Our business is the transport of steel - what role does digitization play in all of this?

As in all areas of life and business, digitization also has a major impact on logistics. We are making increasing efforts to digitally map the entire value chain in order to achieve a wide variety of interlinked goals: On the one hand, digital processes can already be used in production control to optimize the use of resources, make production planning flexible, and optimize maintenance processes. In the networking of all partners involved through digital interfaces, we see the opportunity to create great transparency: The complete process is covered and the customers can see at any time where the order currently stands and whether there are any delays. With the real-time data, better decisions can be made and the individual players can be aligned more effectively. In the near future, we are therefore planning a project for a customer portal where users can access useful information 24/7 (including full tracking of orders in the sense of a seamless digital customer experience).

As you can see: Digitization can also play a role in industries where you might not have suspected it directly at the beginning. We regard digitization as a task that constantly inspires us to come up with new ideas to achieve optimum results for all those involved in the process.

But of course, digitization has also arrived within our organization. We are constantly seeking to identify the processes and interfaces that can be improved through digitization. In this context, we focus on two perspectives: On the one hand, it is important for us to achieve excellence internally by means of flawless cooperation. This includes, for example, the introduction of a new ERP system, which we completed back in 2016. Since then, we have been constantly optimizing process flows, shortening processing times and analyzing data that can give us valuable indications for improvements (business process automation). We have been able to achieve our goal of operating paperless almost completely on our journey, even though there are still work steps here and there that require paper documentation.

We have also been able to achieve smoother workflows in internal cooperation with the switch to O365, which ultimately benefits everyone with whom we have interfaces. For the operation of our ICT system, we rely on cloud technologies, which guarantee us great flexibility and open up room for action. This allows us to easily implement new releases of our ERP system, which require an identical test environment in parallel to the live system.

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Kontakt

Sustainable supply chain excellence - delivered!

We supply and move steel - globally - in numerous specifications - and with typical "made in Switzerland" reliability.

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Plates

Plates - Layer by Layer

Contact us for more details, as our products are available in various specifications and sizes.

Heavy plates are produced hot-rolled in unalloyed and low-alloyed steel grades. We offer heavy plates in tested quality in all common standards for many applications. In addition, we offer hot–rolled slabs, which have a higher thickness than heavy plates and are used as semi-finished material for easier forming processes.

- Structural steel, unalloyed according to EN 10025

- Pressure vessel steel according to EN 10028

- Shipbuilding steels

- Steels for pipes and pipelines – EN 10208

- Weather-resistant plates – EN 10025

- Hot-rolled slabs according to EN 10025

Laminoirs des Landes (LDL) stands for flexible, customer-oriented production with excellent customer service. LDL provides a fast, continuous and reliable supply of heavy plates in the following dimensional range:

| Thickness | 8 – 150 mm | Laminoirs des Landes S. A. S. |

| Width | 1,600 - 3,400 mm | Laminoirs des Landes S. A. S. |

| Length | max. 24,000 mm | Laminoirs des Landes S. A. S. |

in the delivery conditions +AR (rolled condition) or +N (normalized).

Heavy plates are used for wind turbine masts as well as in many other construction and infrastructure projects. Depending on the application, heavy plates are used in agricultural and heavy machinery construction. A further application is shipbuilding, where heavy plates are used in the manufacturing of container ships, bulk carriers, tankers and even leisure yachts. They are also used in the construction of offshore drilling and operating platforms. In general, heavy plates are versatile, so they are commonly found in mechanical engineering.

For applications where high pressure and high temperatures are crucial, our quality portfolio includes unalloyed boiler plates and alloyed steels for pressure vessels as well as sour gas resistant boiler plates for the tank and container construction industry. That’s why you’ll find wear-resistant steels in a variety of grades and plate thicknesses. These are also ideal for applications such as mining technology and in steel and cement plants.

The manufacturer of heavy plates is Laminoirs des Landes S.A.S., based in Tarnos (FR).

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

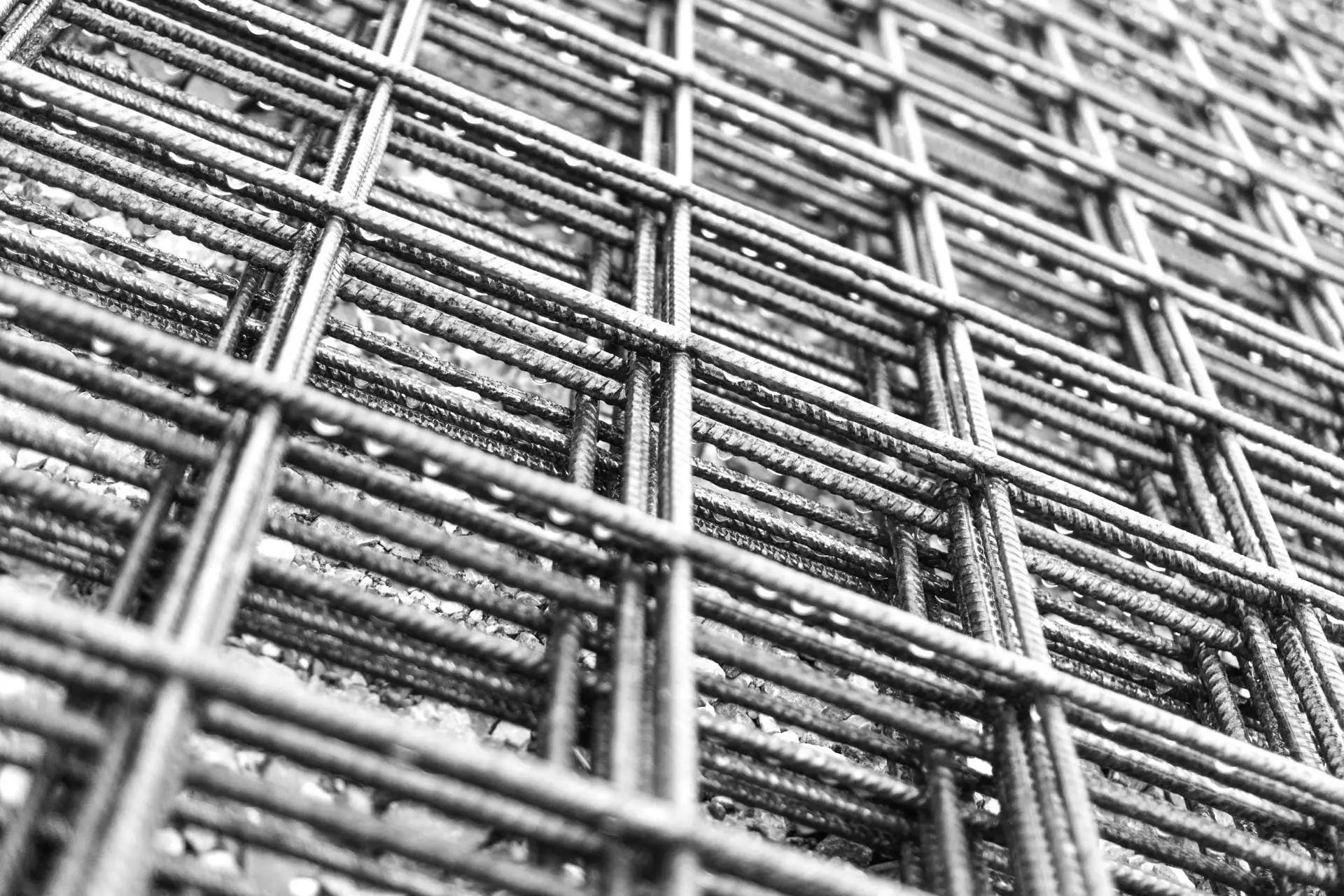

Reinforcement Meshes

Reinforcement Meshes - Practical, Simple and Flexible to Use

Contact us for more details, as our products are available in various specifications and sizes.

Reinforcement meshes (or support meshes) are made of welded bars of reinforcing steel, which are used for the reinforcement of concrete structures – floor slabs, ceilings and walls. Their advantage is that, due to the mesh formats, large areas can be reinforced in a relatively short time.

- according to SIA Norm 262:2013

Reinforcement meshes - structural reinforcement

| Quality K 188 / K 283 / K 335 | Format 2,0 x 5,0 m | Ferriere Nord S.p.A. |

The monitoring of the quality classes is carried out by our manufacturer.

With reinforcement meshes large areas can be laid in a short time. This makes it possible to efficiently progress in residential and industrial construction. Reinforcement meshes are also used in road and bridge construction as well as in underground and above-ground parking garages. Reinforcement meshes are also used in prefabrication.

The manufacturer of reinforcement meshes is Pittini Srl.

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

Sectional Steel

Sectional Steel - Attractive Shapes with a Supporting Role

Contact us for more details, as our products are available in various specifications and sizes.

Sectional Steel / Wide Flange Beams

These components have a load-bearing function in buildings. The material can carry heavy loads and is particularly resistant. For example, platforms can be inserted in high buildings forming an intermediate level. Steel structures are also used in hall construction.

Sectional steel / wide flange beams are produced in hot-rolled execution.

- Unalloyed structural steel according to EN 10025

| HEA dimension 100 – 200 mm | length 6 – 18 m | AFV Acciaierie Beltrame S.p.A. |

| HEB dimension 100 – 200 mm | length 6 – 18 m | AFV Acciaierie Beltrame S.p.A. |

| UNP dimension 80 – 240 mm | length 6 – 15 m | AFV Acciaierie Beltrame S.p.A. |

| UNP dimension 80 – 120 mm | length 6 – 15 m | Acciaierie Venete S.p.A. |

| IPE dimension 80 – 240 mm | length 6 – 18 m | AFV Acciaierie Beltrame S.p.A. |

The manufacturers of sectional steel / wide flange beams are Acciaierie Venete SpA and AFV Beltrame SpA.

Our quality standard with regard to the environment, energy, occupational safety, etc. is confirmed by a large number of certificates.

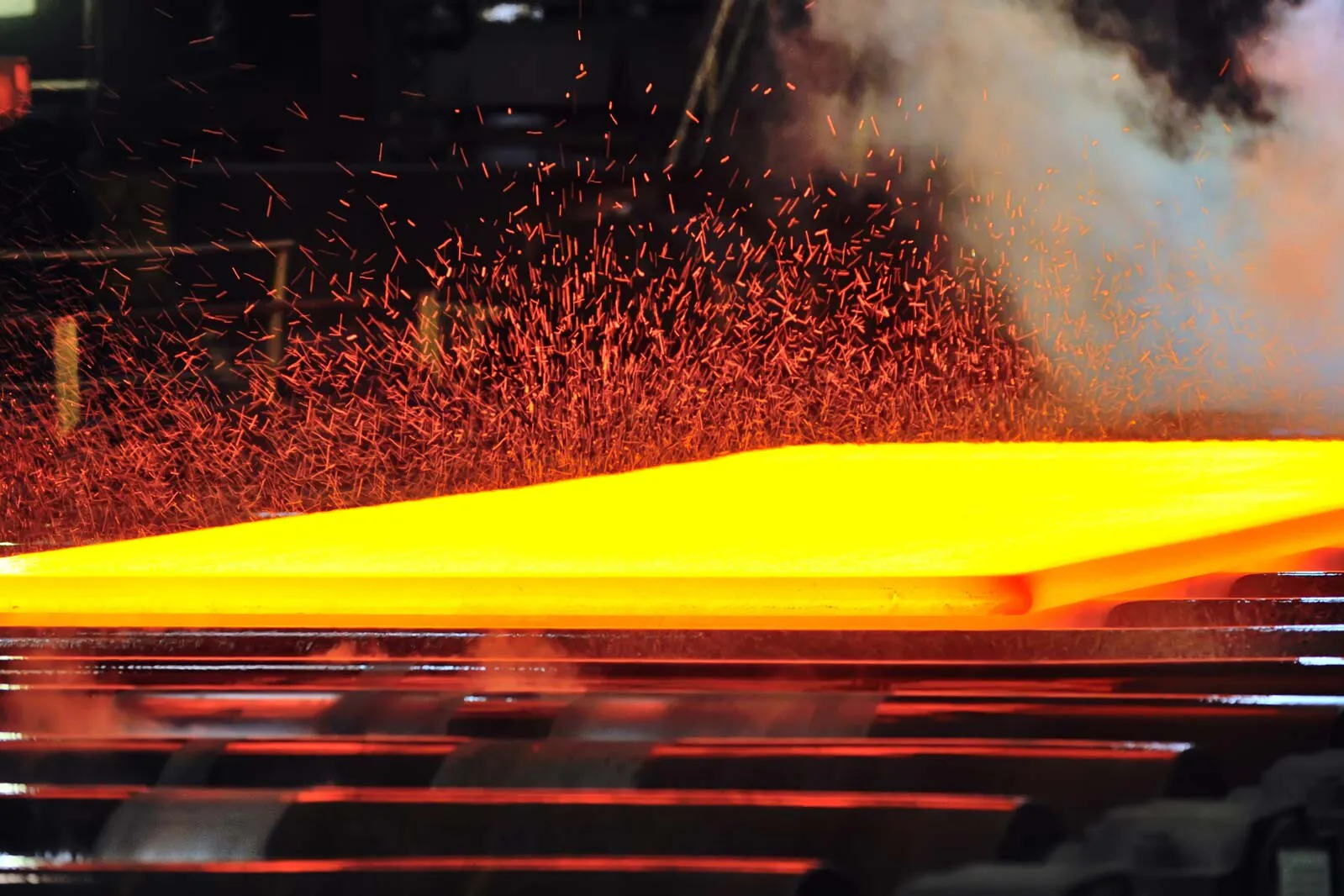

Crude Steel

Crude Steel – Steel for Semi-finished Products with a Wide Range of Applications

Contact us for more details, as our products are available in various specifications and sizes.

Liquid steel is cast in a so-called ingot mold (continuous casting), where solidification takes place. This way, crude steel is produced, which can then be further processed for various applications.

SIPRO® STEEL SOLUTIONS supplies the untreated steel in round, square or rectangular ingots for massive forming as well as special applications (e.g. profiles).

- Unalloyed structural steel according to EN 10025

- Steels for quenching and tempering according to ISO 683-1 up to 2

- Case hardening steel according to ISO 683-3

Massive forming and Special Applications

| Squares 160x160 mm | length 4,5 – 5,7 m | Acciaierie Venete S.p.A. |

| Squares 120x120, 140x140, 160x160 mm | length 4,5 – 12 m | Acciaierie Venete S.p.A. |

| Rounds 200/240/280/350/420/600 mm | length 4,5 – 8 m | Acciaierie Venete S.p.A. |

| Rounds 140/180 mm | length 4,5 – 8 m | Acciaierie Venete S.p.A. |

| Rectangulars 220x160, 240x200, 300x160 mm | length 4,5 – 5,7 m | Acciaierie Venete S.p.A. |

Like many other raw materials, crude steel can be used in a wide variety of areas after having been processed, and even very small products can play an important role. Flanges or forged rings may weigh a few grams, but they are elementary in mechanical and plant engineering, in vehicle and gear manufacturing, and in the energy sector, where oil and gas have to be stored and transported.

Rolled rings can be relied on in excavators, cranes and lifting equipment, as well as in tunnel construction and building machinery. Special profiles for lifting equipment or guide rails are also among the products made of crude steel.

The manufacturer of crude steel is Acciaierie Venete SpA.